Choosing the best IoT protocol: WiFi, GSM, or Bluetooth

In the world of IoT, choosing the right communication method is never a trivial task. The decision between WiFi vs GSM vs Bluetooth in IoT directly affects critical aspects such as battery life, data rate, coverage, and overall cost. Whether you are developing wearables, industrial sensors, or smart home devices, the communication protocol you select will determine how efficiently and reliably your embedded system performs. This guide explores real-world use cases and trade-offs, helping you identify the best protocol for your project.

What to consider before choosing a protocol

First, you should evaluate the following criteria:

- Range & Coverage Needs — Does the device need to work indoors, outdoors, or across large areas?

- Data Rate & Latency — Will the device send periodic small messages, or heavy data streams (e.g. video)?

- Power & Battery Life — Is the device battery powered, or can it assume constant power supply?

- Cost & Infrastructure — What are the costs of hardware, connectivity (e.g. SIM cards), and ongoing service?

- Security & Regulatory Concerns — Are licensed spectrum or operator-certified protocols required?

These factors will guide your choice between WiFi, GSM, Bluetooth, and other protocols like LPWAN.

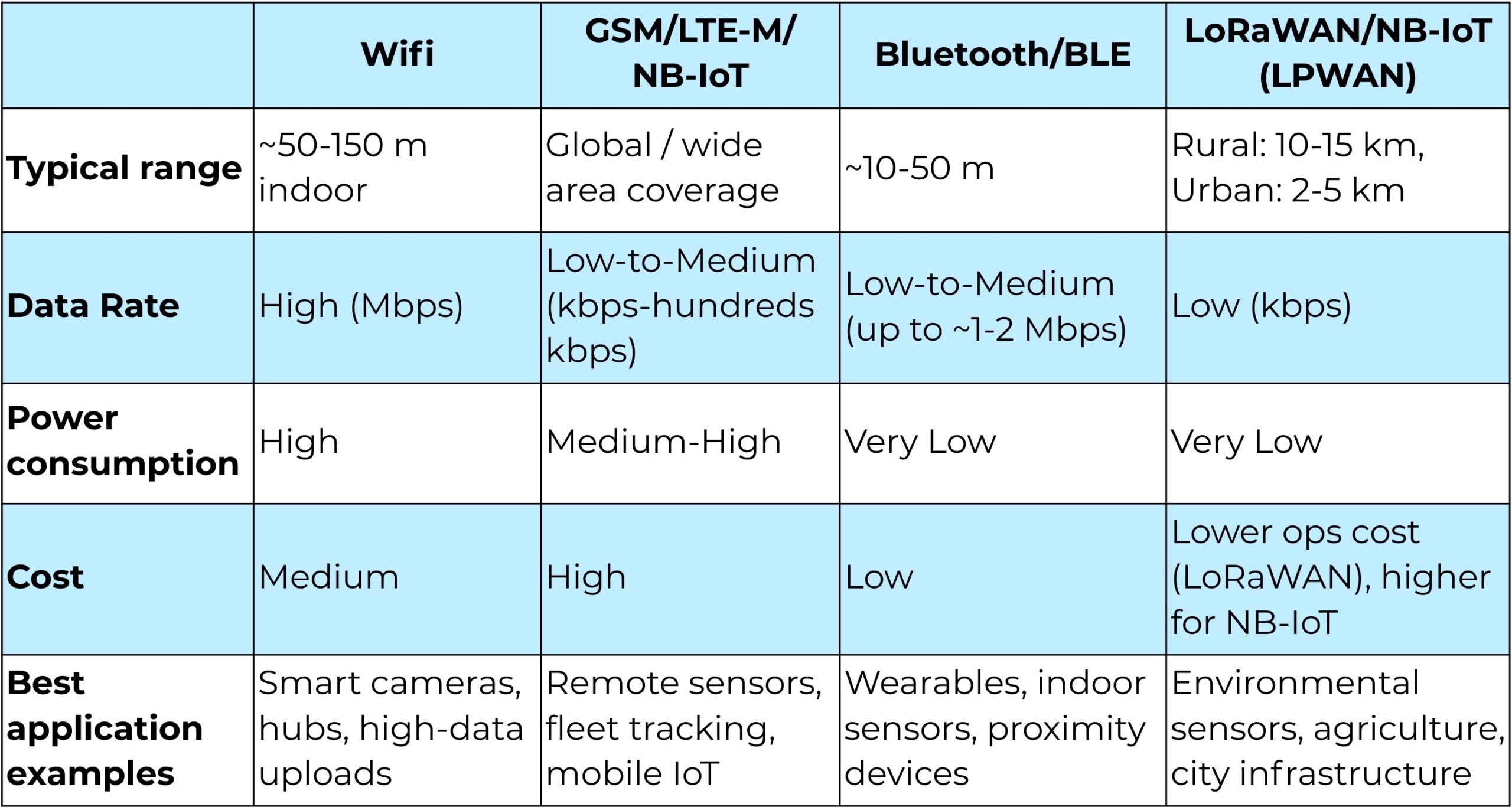

WiFi: high throughput with local convenience

WiFi offers high data rates, typically in the range of tens to hundreds of Mbps and is excellent when your IoT device operates in a space with existing network infrastructure (home, office). Because of this, it’s often used in smart cameras, video-streaming devices, or hubs that upload many data packets.

However, WiFi also has trade-offs: it consumes more power, which shortens battery life, and setup (security, routers, interference) can become complicated in challenging RF environments. Furthermore, its range is limited relative to cellular or LPWAN options, especially outdoors. Referencing IoT comparison studies, choosing Wi-Fi makes sense when bandwidth and latency are priorities and power is less constrained.

GSM / Cellular: wide reach at a price

Meanwhile, GSM (including modern cellular IoT technologies like LTE-M / NB-IoT) gives you almost global coverage, mobility, and reliable indoor penetration. Because of this, it is often chosen for fleet tracking, remote sensors, or devices outside the reach of WiFi.

Yet, cellular connectivity typically incurs higher costs (SIM cards, data plans), higher baseline power consumption, and sometimes more expensive certification and hardware. In many use cases, the cost-benefit balance swings toward GSM only when you truly need wide area coverage or remote deployment.

Bluetooth / BLE: low power, short range, big in wearables

On the other hand, Bluetooth Low Energy (BLE) is superb for short-range, low-data scenarios. When power efficiency is paramount—such as in wearables, health sensors, or indoor smart home devices—BLE shines. Because its power draw is low, and its data rates are sufficient for many non-

streaming use cases, it often maximizes battery life.

Nevertheless, Bluetooth’s downsides include limited range (tens of meters), potential interference in crowded frequency bands (2.4 GHz), and lower data throughput. Therefore, it’s less suited to situations needing long range, frequent connectivity, or high volumes of data.

Emerging Alternatives: LPWAN (LoRaWAN, NB-IoT) for long range & low power

- LoRaWAN operates on unlicensed spectrum, has very low power demands, and can cover up to 10-15 km in rural areas (2-5 km in urban settings). However, its data rate is modest and latency can be higher.

- NB-IoT uses licensed cellular bands, giving better reliability and penetration, somewhat higher data rates (up to ~200 kbps), though at higher cost in hardware and network subscription. Battery life is still strong, but depends heavily on transmission frequency and network conditions.

Thus, LPWAN options are often the best choice when covering remote sensors, environmental monitoring, smart agriculture, and city-scale deployment.

Comparison Matrix: Wi-Fi vs GSM vs Bluetooth vs LPWAN

Decision Flowchart: which protocol fits your IoT use case?

To simplify your choice, here’s a flowchart logic you can follow:

- Do you require long-range or remote coverage?

-

- Yes → Consider GSM or LPWAN

- No → Go to step 2

-

- Is power / battery life a critical constraint?

-

- Yes → Bluetooth / BLE or LPWAN

- No → Go to step 3

-

- Do you need high data rate or streaming capability?

-

- Yes → WiFi or high-bandwidth cellular

- No → Lower bandwidth options are acceptable

-

- Do you have existing connectivity infrastructure or constraints (e.g. operator support, licenced spectrum)?

- What is the budget (both device cost and ongoing connectivity)?

Using this flow, you can map your use case to the protocol that matches your priorities in range, power, cost, and data.

Real-world use cases

- Smart Surveillance Camera (Home or Business): Needs high resolution video, frequent uploads → WiFi is typically the best fit.

- Agricultural Field Sensor: Long range, minimal data (e.g. temperature, humidity), solar or battery powered → LoRaWAN or NB-IoT works well.

- Wearable Health Monitor: Low power, periodic data syncing to mobile → BLE is a strong choice.

- Vehicle Telematics: Mobility + remote coverage → GSM / LTE-M or NB-IoT depending on region and data frequency.

Final thoughts: balancing trade-offs for embedded system design

Ultimately, choosing between WiFi vs GSM vs Bluetooth in IoT requires balancing trade-offs:

- If you prioritize bandwidth and speed, WiFi or high-bandwidth cellular is preferable.

- If power efficiency is paramount, Bluetooth / BLE or LPWAN protocols shine.

- If coverage is the key concern (remote or mobile), then GSM or LPWAN is usually the answer.

- If cost (hardware + connectivity) or infrastructure limitations exist, that steers decision toward Bluetooth/BLE or LoRaWAN.